On Demand and Supply Adjustment in Food Manufacturers

FLEXSCHE Corporation Yosuke Higuchi

Published Article in 'Instrumentation' 2012. Vol.55 No.9

1. Introduction

A "Product Demand and Supply Adjustment Reform Project" was launched at a certain food manufacturer (hereafter referred to as Company A), but the objectives could not be achieved.

Using Company A as a case study, I would like to examine the factors that prevented the reform, the issues and their countermeasures, and the ideal state of product demand and supply adjustment operations in future food manufacturers.

2. Flow of Demand and Supply Adjustment Operations at Company A

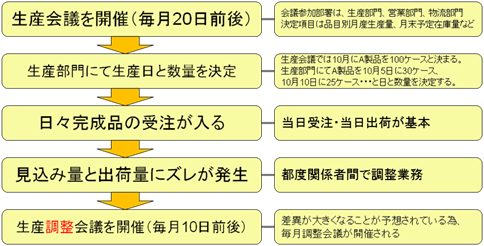

Process for determining October's production quantity (Figure 1)

- Holding of production meetings (also known as sales and production meetings)

- The production, sales, and logistics departments gather at the headquarters around September 20.

- The sales department presents the sales landing forecast for September and the sales plan for October.

- The end-of-month inventory quantity for September is forecasted, and the production quantity for October is determined for each product.

- The production department determines the production timing and quantity for each product.

- The production quantity for October is divided by the number of business days and converted into daily shipment forecast information.

- The end-of-month inventory for September is subtracted from the daily shipment forecast information, the timing when it falls below the safety stock is measured, and the daily production quantity for each product is determined while considering the daily load of the factory, which has finite capacity. *1

- Products are shipped from inventory based on daily orders (at Company A, orders = immediate shipment).

- A discrepancy arises between the shipment information and the shipment forecast calculated in step 2.

- Holding of production adjustment meetings (also known as sales and production adjustment meetings) *2

- Due to discrepancies between the expected production quantity and daily shipment quantity, the production, sales, and logistics departments gather at the headquarters around October 10 to adjust the production quantity.

- The production quantity is adjusted until the end of October.

- The production department determines the production timing and quantity for each product, similar to step 2.

*1: This operation requires know-how, leading to a tendency for planning to become personalized.

*2: The production adjustment meeting is based on the premise that discrepancies will arise between the expected quantity and shipment quantity. At Company A, there was frequent discussion about whether the number of demand and supply adjustment meetings should be increased.

Figure 1 Production Quantity Determination Process

3. Emerging Issues

Issue 1: Distrust of the Sales Department by the Production Department (Forecast Accuracy is Everything)

At Company A, discrepancies between expected quantities and shipment quantities occurred monthly across various products, leading the production department to be overwhelmed with demand and supply adjustments, which also spread confusion to the production site. From the confusion and fatigue, the production department expressed distrust, saying, "It's because the numbers presented by sales are unreliable that we end up in such a mess." In production meetings, statements expressing distrust, such as "Can we really trust these numbers?" and "Even if they say they'll sell, they probably won't sell that much," were rampant. In such a situation, a good meeting cannot be held. Amidst this, a proposal was made by the production department: "With the advancement of IT, there must be highly accurate demand forecasting tools out there. Wouldn't it be more accurate to forecast demand using these tools rather than relying on the sales department's numbers?" It was a desperate suggestion. Company A investigated demand forecasting tools, but unfortunately, there were no tools available at a level that could be used for business. Many people believed without doubt that "if the forecast accuracy is high, demand and supply adjustments will go well."

Issue 2: Stock Shortages

One day at Company A, a product that no one had been paying attention to suddenly went out of stock. The cause of the shortage was unknown, and the shortage information spread to the distribution side. The distribution side scrambled to gather the out-of-stock product. Until the shortage was resolved, the response to the situation was like a storm, making it difficult to quickly identify the factors that caused the shortage.

After the shortage was resolved (a few days later), an investigation revealed that the daily shipment volume had increased from a certain day. The cause was a statement made by an influential celebrity on television, saying, "Recently, I feel better when I eat this product." It was impossible to predict the celebrity's statement.

Incidentally, in chronological order,

- July 15: Celebrity's statement (unnoticed by anyone at Company A)

- Increase in shipment volume

- Product shortage

- Establishment of increased production system

- Shortage resolution

- It was discovered at Company A that the cause was the celebrity's statement

The overreaction of the distribution side is reflected in the volume of purchase orders (including EDI orders) to the manufacturer. When the order volume increases, it becomes difficult to discern whether the orders are genuinely needed or are overreactions, leading to further confusion. In the midst of groping in the dark, the sales department rushes to coordinate with the distribution side, the production department reviews plans daily to prevent chain shortages, and the logistics department struggles with how to allocate the limited inventory to each distribution center. Stock shortages cause significant losses for manufacturers, including opportunity losses and increased indirect costs.

Issue 3: Product Inventory Disposal

One of the major constraints in the food manufacturing industry is the expiration date. Since the distribution side places importance on the manufacturing date (expiration date) as freshness, unsold products must be discarded if their freshness declines. Products that sell well can maintain freshness if produced and shipped daily. Products that do not sell well (C-rank products in ABC ranking) are rarely produced or shipped daily. Additionally, their forecasted demand is difficult to predict. As a result, there are cases where product inventory must be discarded. Since C-rank products have low production volumes, the cost of disposal may be within an acceptable range. The serious issue lies with new products and campaign products. Products that receive an internal directive to "focus on expanding sales" are planned to have large inventories. However, if they do not sell, the loss from product disposal is significant, resulting in a major loss. Moreover, it is not eco-friendly.

Problem 4: Sales Department Making Sudden Requests

When the supply-demand balance becomes disrupted (especially when shipments exceed forecasts), the sales department suddenly requests increased production of a certain product from the production department. If the production department hesitates to respond, the sales department uses a catchphrase: "If it sells, we must sell it, or the company's performance will..." This catchphrase makes the production department feel that the responsibility is being shifted to them, and the sales department tries to force the production department to supply the target product. Why does the sales department make sudden requests in the first place? It is likely because they do not notice the daily discrepancies between forecasted and actual shipment volumes. As mentioned earlier, when planning, the production department balances the factory load, production lots, and timing to avoid stockouts across multiple items. However, the sales department finds it difficult to understand how challenging it is to plan for the factory, leading to repeated irresponsible requests.

Problem 5: Production Department Unable to Respond Flexibly to Requests

The sales department says, "Why don't you respond immediately to production adjustment requests? If you could respond quickly, we could take other measures." After production meetings, the production department took several days to formulate when and how much to produce for each product. The reason it takes time is that the planning personnel, who have become specialized, are formulating plans while "pencil-licking." Even when daily supply-demand balance adjustments are necessary, the same process is required, making it impossible to respond immediately to sales.

4. Countermeasures to Problems

Regarding "Production Department Distrustful of Sales Department (Forecast Accuracy is Everything)"

The author believes there is a limit to improving the accuracy of forecast quantities. Even using demand forecasting tools, it is unlikely to improve forecast quantity accuracy beyond expectations. Even if the sales department makes efforts within their capabilities, many highly uncertain factors are involved in calculating forecast quantities, making it unlikely to achieve a perfect score every month. The production department should recognize that there is a limit to improving forecast accuracy. They should consider a system that can respond quickly even if there is a discrepancy between forecast quantities and shipment volumes. In other words, the countermeasure needed is a "system that can adjust supply and demand regardless of forecast accuracy."

Regarding "Stockouts" and "Inventory Disposal"

The causes of "stockouts" are diverse, beyond just celebrity statements, but let's consider an example where a celebrity's statement stimulated demand for a target product. Company A was unaware of the celebrity's statement until the stockout was resolved, so they perceived it as a "sudden stockout." In reality, daily shipment volumes were increasing (diverging from forecast quantities), so if they had not overlooked this fact, they would not have perceived it as a "sudden stockout." Furthermore, if they had detected the "disruption in the supply-demand balance" and quickly adjusted supply and demand, they might have avoided the stockout. Specifically, if they had adjusted the supply-demand balance promptly after July 16, it is regrettable.

"Inventory Disposal" occurs when shipment quantities are less than forecast quantities, leading to excess inventory and ultimately disposal. Monitoring forecast quantities and daily shipment volumes and being able to adjust supply and demand could potentially reduce disposal quantities.

To prevent "stockouts" and "inventory disposal" in advance, it is necessary to continuously monitor the daily supply-demand balance and have a system that can quickly adjust when the balance is disrupted. However, in reality, is it feasible to continuously monitor the supply-demand trends of all products when there are many products being produced in the factory (about 200 products at Company A's factory)? Considering this, a mechanism is needed to make people aware of changes in the supply-demand balance. In other words, the countermeasure needed is a "system to monitor the daily supply-demand balance of many products, quickly adjust it, and make people aware of changes in the supply-demand balance."

Regarding "Sales Department Making Sudden Requests"

The sales department is likely aware that the factory produces with finite capacity. However, they do not understand how difficult it is to plan in the factory. Therefore, they use catchphrases. First, shouldn't the sales department also utilize a system to monitor the supply-demand balance? This would reduce sudden requests. Furthermore, by monitoring the supply-demand balance in both the production and sales departments, it becomes a double-check, strengthening the monitoring system. Next, the sales department should be made to understand more deeply how difficult it is to plan in the factory. Specifically, they should be shown how the factory's plan changes due to the sales department's requests, such as "as a result of accelerating this product, this many products had to be decelerated." This would reduce the frequency of catchphrases. In other words, the countermeasure needed is a "system for monitoring the supply-demand balance in the sales department and visualizing the production planning status."

Regarding "Production Department Unable to Respond Flexibly to Requests"

Why does it take time for production planning tasks? First, let's consider the constraints that must be considered in production planning in the food manufacturing industry.

- The timing when daily shipment forecasts fall below safety stock

- Production capacity on each product's production line

- Production lot of each product

- Expiration date of each product

- Timing of raw material arrivals

These are some of the considerations. For example, when planning for 200 products, one unknowingly processes a vast amount of information. The planner handles this vast information based on intuition and experience, which takes considerable time for planning tasks. As a countermeasure, a "system that can quickly plan considering manufacturing constraints such as factory load" is needed.

5. Conclusion

The reasons why Company A could not reform the "product supply-demand adjustment operations" are:

- They were fixated on the accuracy of forecast quantities

- There was no system to monitor and adjust the daily supply-demand balance

- There was no system for automatic scheduling considering factory load

Company A developed software in-house to address the "product supply-demand adjustment operations," but the reform did not progress due to the vast amount of information handled, the inability to effectively visualize it for easy human judgment, and the inability to quickly plan considering manufacturing constraints such as load. So, how should the supply-demand adjustment operations of food manufacturers be in the future? I would like to summarize this below.

- It is important for the production department to have the mindset of "flexibly adjusting supply and demand even if the forecast accuracy is low."

- Monitor the daily supply and demand balance of numerous products, enabling swift adjustments and alerting personnel to changes in the supply-demand balance.

- The sales department should also monitor the supply-demand balance and be able to grasp the production planning status.

- Be able to quickly formulate plans that consider manufacturing constraints such as factory load.

To build these systems, it is essential to utilize software due to the vast amount of information handled and the need for quick daily responses. Many other food manufacturers face similar issues as Company A. Why not consider what the ideal supply-demand adjustment operations should be?

6. The Emergence of FLEXSCHE d-MPS

In June 2012, our company launched "FLEXSCHE d-MPS."

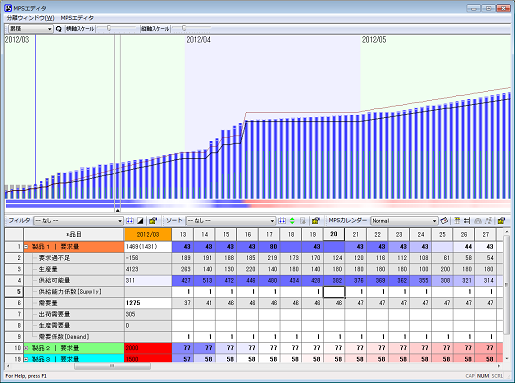

FLEXSCHE d-MPS (Figure 2) allows for visual monitoring of daily supply-demand balance and enables swift adjustments as needed. It also allows planning based on the true production capacity of the factory. The name FLEXSCHE d-MPS signifies the dynamic updating of plans to reflect daily demand fluctuations, unlike the traditional MPS (Master Production Schedule) where plans are fixed.

FLEXSCHE d-MPS is sure to bring innovation to the supply-demand adjustment operations of food manufacturers.

Figure 2 Central Window of FLEXSCHE d-MPS