Partner Introduction UIS

Interview Date: December 2022

UBE Information Systems, Ltd. (hereinafter referred to as UIS), which has been proposing and implementing planning software for the manufacturing industry for nearly 30 years, leverages its experience, know-how, and technical capabilities to propose and implement FLEXSCHE for manufacturers nationwide.

Profiles

Business Solutions Division

Mr. Kazunori Otsuka

Solution Sales Department

Director

-

Business Solutions Division

Mr. Tomonori Hisaka

Solution Development Department

Manager

-

Business Solutions Division

Mr. Kota Kazuki

Solution Sales Department

-

Business Solutions Division

Mr. Takuya Fujimoto

Solution Development Department

-

Business Solutions Division

Mr. Yoshinao Asami

Solution Sales Department

-

Business Solutions Division

Mr. Mio Mochizuki

Solution Development Department

-

Business Solutions Division

Mr. Tatsuya Hirata

Solution Sales Department

Encounter with FLEXSCHE

-

FLEXSCHE

FLEXSCHE

-

Suddenly, could you tell us the current number of installations?

-

Otsuka

Otsuka

-

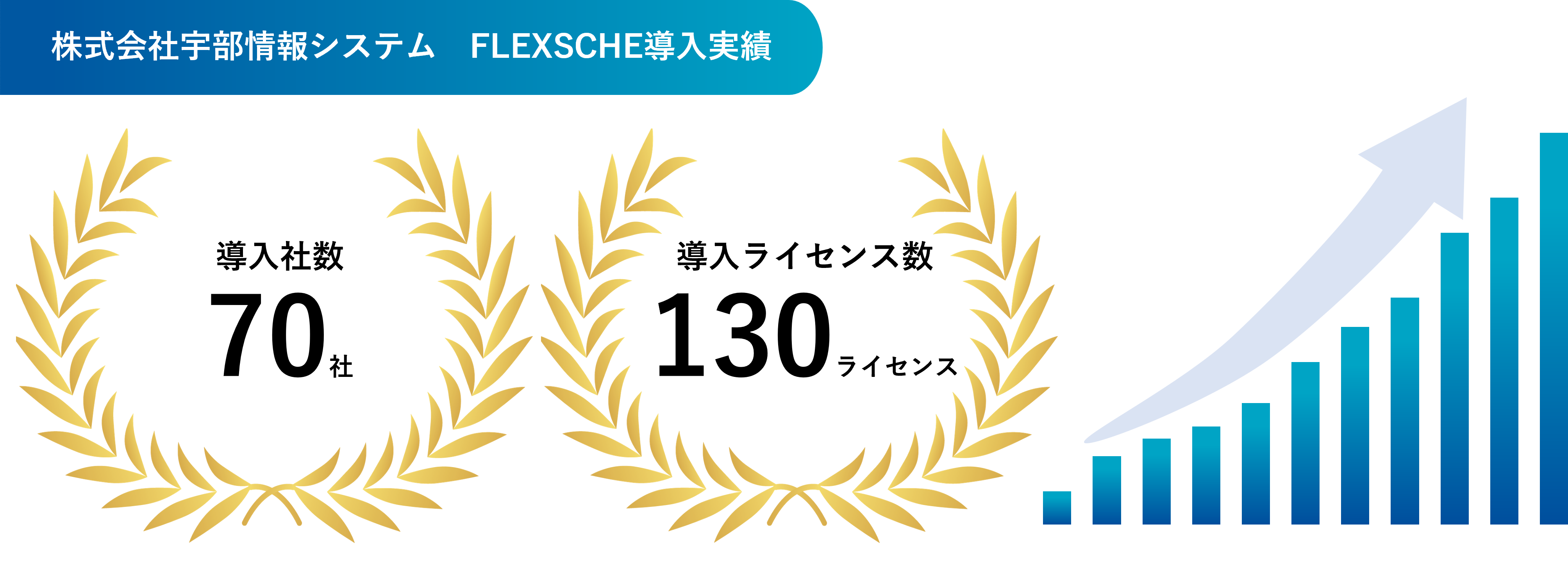

We have implemented 130 licenses for 70 companies in the manufacturing industry nationwide (as of March 2023). Our customers come from various industries, including heavy industry, food, chemicals, and industrial machinery.

-

FLEXSCHE

FLEXSCHE

-

UIS is perceived as a veteran partner of FLEXSCHE, but when did you start supporting the implementation of FLEXSCHE?

-

Otsuka

Otsuka

-

We started supporting the implementation of FLEXSCHE around 2003, so it has been about 20 years now.

-

FLEXSCHE

FLEXSCHE

-

20 years! Since FLEXSCHE Corporation was founded in 2001, you've been involved with FLEXSCHE since shortly after its release.

-

Hisaka

Hisaka

-

Yes, that's right. Before encountering FLEXSCHE, we were implementing other planning software for the manufacturing industry. Therefore, we have been involved in the implementation of planning software for the manufacturing industry for nearly 30 years.

-

FLEXSCHE

FLEXSCHE

-

What was the trigger that led you to handle FLEXSCHE?

-

Otsuka

Otsuka

-

Originally, we were supporting the implementation of other planning software, but as production planning in the manufacturing industry became more complex and customer requirements became more advanced, that planning software could no longer keep up. While searching for other planning software, we came across FLEXSCHE.

-

FLEXSCHE

FLEXSCHE

-

What aspects of FLEXSCHE did you find appealing?

-

Hisaka

Hisaka

-

FLEXSCHE is a package product, yet it offers both high flexibility and extensibility, allowing us to leverage our know-how to thoroughly pursue ease of use tailored to customer needs.

Recent FLEXSCHE Implementation Projects

-

FLEXSCHE

FLEXSCHE

-

Recently, I've heard that the needs for planning in the manufacturing industry are becoming more complex and the standards required for planning software are rising. What is the actual situation?

-

Otsuka

Otsuka

-

Yes, indeed, I feel that the needs of each project are becoming more complex.

-

FLEXSCHE

FLEXSCHE

-

It might be difficult to answer, but how do you perceive FLEXSCHE from your perspective?

-

Kazuki

Kazuki

-

Well, even though it's a package software, its flexible adaptability to meet customer demands is remarkable. It fits a wide variety of industries and factories, so we can propose it to any manufacturing customer.

-

Hirata

Hirata

-

Seeing the development team working hard to utilize FLEXSCHE's functions to meet customer requirements, I realize the high performance and flexibility of FLEXSCHE.

-

Fujimoto

Fujimoto

-

FLEXSCHE allows for the flexible setting of complex modeling and scheduling rules, enabling us to reproduce customers' planning operations at a high level. Even with standard features, many things can be achieved, and detailed customization is possible, allowing us to provide a truly user-friendly scheduler for our customers.

-

FLEXSCHE

FLEXSCHE

-

How is the number of recent projects? Do you notice any trends?

-

Hisaka

Hisaka

-

Recently, the demand for planning software has increased, with about 4 to 6 projects running concurrently. In terms of industry, there are many related to chemicals and food, and the number of batch process manufacturers is increasing.

-

FLEXSCHE

FLEXSCHE

-

I've heard that UIS has many ongoing projects. What is the ratio of ongoing projects?

-

Otsuka

Otsuka

-

Overall, new projects account for about 20%, ongoing projects for about 50%, and collaborative projects with other partners for about 30%.

-

FLEXSCHE

FLEXSCHE

-

There are so many collaborative projects with other partners!

-

Asami

Asami

-

Through FLEXSCHE implementation projects, we have been increasingly involved with various partners. FLEXSCHE Corporation hosts events such as partner meetings and study sessions, providing many opportunities for partner interaction, which expands connections with other partners. We collaborate with other partners to address customer challenges.

-

FLEXSCHE

FLEXSCHE

-

In recent years, "DX" and "Smart Factory" have been gaining attention in the manufacturing industry. Do you receive many consultations on these topics?

-

Asami

Asami

-

Yes, they are increasing more and more recently. Many of these customers are in a hurry.

-

FLEXSCHE

FLEXSCHE

-

We feel that FLEXSCHE is also expected to be utilized for realizing DX and Smart Factory.

-

Asami

Asami

-

On the other hand, we also receive many consultations seeking to eliminate the personalization of planning operations and promote factory visualization for operational efficiency.

-

Kazuki

Kazuki

-

There are still quite a few manufacturers who plan production using Microsoft Excel or manage it with a whiteboard. With FLEXSCHE, once it is up and running, you can plan with the push of a button, which makes the efficiency improvement visible and tangible.

-

Asami

Asami

-

However, in reality, achieving such efficiency is rarely the ultimate goal; more often, the true goal is the subsequent business improvement. Therefore, we believe it is our role to propose that aspect firmly.

-

Kazuki

Kazuki

-

For example, once a factory model is built in FLEXSCHE, it allows for factory operation simulations at any time. This can be utilized for inventory reduction, load-considered planning, and more efficient manufacturing planning, with various expected effects. By expanding the scope of utilization, it should also lead to achieving significant goals such as "increasing production efficiency by X%."

-

Otsuka

Otsuka

-

In the past, there were voices citing cost-effectiveness, such as "Currently, there are three planning personnel, and if it becomes one, it will pay off to this extent," but recently, we haven't heard much of that. Rather than cost-effectiveness, we feel that current customers have expectations for FLEXSCHE that go beyond mere efficiency improvement.

-

Kazuki

Kazuki

-

There are cases where FLEXSCHE becomes necessary while proposing other business systems. Originally, we proposed our ERP solution "UP-One," which is specialized for our converting business (flexible packaging film processing, high-performance film processing) and film raw material manufacturing and processing business. However, as we discuss with customers, there are requirements that cannot be fulfilled by UP-One alone. That's where FLEXSCHE comes in. As a core system, it is strong in its ability to centrally manage various information, but it has some weaknesses in the area of "planning," which FLEXSCHE complements.

-

FLEXSCHE

FLEXSCHE

-

I see. How do you introduce FLEXSCHE to your customers in the first place?

-

Kazuki

Kazuki

-

We sometimes show the samples prepared with FLEXSCHE, and as the business discussions progress, we create prototypes using the customer's actual data to help them visualize the actual operation.

-

Asami

Asami

-

Customers often express the desire to "see it with our own items," which helps them have a more concrete image of the implementation.

-

FLEXSCHE

FLEXSCHE

-

By the way, I remember that Mr. Kazuki and Mr. Asami also participated in the prototype study session we held the other day. Are the prototypes created by the sales team?

-

Kazuki

Kazuki

-

Previously, we would have the development team handle the constraints we heard, or we would select and show samples created by FLEXSCHE Corporation. However, now the sales team handles the simpler ones.

-

Asami

Asami

-

It's difficult for us to create complex ones, but after watching the training and trying it ourselves, we find it interesting and challenging. I think it was easier for me to get into it because I used to work in the manufacturing industry and had field knowledge.

-

Kazuki

Kazuki

-

Recently, we've been hearing more from customers who have already implemented FLEXSCHE, saying things like "I want to implement it in other factories" or "I want to review the production plan, so I want to review the FLEXSCHE settings."

-

Asami

Asami

-

It's gratifying because it means that the effects of implementing FLEXSCHE are being recognized, leading to such discussions.

-

Hisaka

Hisaka

-

Even though we have years of experience with implementation, there are times when we internally feel anxious about whether we are meeting the requirements appropriately. Hearing such stories makes us realize that we have been helpful.

-

FLEXSCHE

FLEXSCHE

-

During the implementation project, what points are particularly challenging?

-

Hisaka

Hisaka

-

The most challenging part is organizing the requirements. We need to understand and organize the customer's business by listening to each process flow and constraint, and then incorporate it into FLEXSCHE. It's a demanding task that cannot be done overnight, as we must proceed while understanding the customer's manufacturing flow, but we are working diligently to accurately understand the customer's work.

-

Mochizuki

Mochizuki

-

In industries like the chemical sector, where invisible materials like liquids and gases are handled, it is even more challenging because the materials and unit quantities change multiple times during the manufacturing process, making it difficult to solidify the image. There are many technical and industry-specific terms in the customer's data, so we proceed by understanding each term one by one.

-

Hisaka

Hisaka

-

Instead of trying to hear the requirements from the start, we begin by showing the actual planning operations as they are, and then delve into what the customer takes for granted, organizing them as requirements. It is indeed a challenging task, but we strive to understand the customer correctly.

-

FLEXSCHE

FLEXSCHE

-

Is there anything you pay attention to during the implementation project?

-

Hisaka

Hisaka

-

We try to receive data from the customer as soon as possible. No matter how much we refine the requirements definition and proceed with the implementation, issues often become apparent only when the data is actually input into FLEXSCHE.

-

FLEXSCHE

FLEXSCHE

-

By importing data into FLEXSCHE, it becomes visualized and a common understanding is formed, making it easier to proceed with discussions.

-

Hisaka

Hisaka

-

That's right. To ensure the success of the implementation project, we ask customers to prepare the data as soon as possible.

FLEXSCHE business

Expanding the team to further grow

-

FLEXSCHE

FLEXSCHE

-

Could you tell us about the future policy regarding the FLEXSCHE business?

-

Otsuka

Otsuka

-

As a company, we are expanding the FLEXSCHE business. We are currently increasing our personnel. Previously, the FLEXSCHE team consisted of just a few members centered around myself and Hisaka, so we always felt like we were "lacking teammates." With the timing of organizational changes and my promotion to management, we have finally been able to increase the number of personnel in both the sales and development teams in recent years, and now several members, including those present here, are working as the FLEXSCHE team.

-

FLEXSCHE

FLEXSCHE

-

Does that mean that with more members, you can handle more projects?

-

Otsuka

Otsuka

-

With the increase in team members, we can handle more projects simultaneously, and we have been able to implement many FLEXSCHE installations.

-

FLEXSCHE

FLEXSCHE

-

I heard that Mr. Mochizuki and Mr. Fujimoto have not been involved with FLEXSCHE for long. How do you find it now that you are involved?

-

Mochizuki

Mochizuki

-

I've only been with UIS for about a year. I was an SE handling CAD systems in my previous job, but I think FLEXSCHE is the most complex software I've dealt with so far.

-

Fujimoto

Fujimoto

-

I've been involved with FLEXSCHE for about three years now, and like Mr. Mochizuki, I struggled a lot at first.

-

FLEXSCHE

FLEXSCHE

-

How do the developers learn about FLEXSCHE?

-

Hisaka

Hisaka

-

After taking the training provided by FLEXSCHE Corporation, we have them get involved in actual projects as much as possible.

-

FLEXSCHE

FLEXSCHE

-

So, they start working on real projects right after completing the training.

-

Hisaka

Hisaka

-

Yes. We believe that it is more important to talk with customers and properly understand their perspective than to learn from texts and materials.

-

Mochizuki

Mochizuki

-

In reality, working on implementation tasks requires complex processing, so there is much to learn from it. However, we also heavily utilize the knowledge gained from training to understand the content, so the foundational knowledge acquired during training is also important.

-

Fujimoto

Fujimoto

-

I also learned a lot from implementation projects. I think I managed to gain some skills through that. When I was troubled, I referred to past project examples and samples, researched them, and implemented them while getting hints from what seemed usable.

-

Hisaka

Hisaka

-

Even in projects led by younger members, veterans can step in to support and follow up whenever needed, so we entrust them with more responsibilities. In the future, we want to further develop an environment where young members can grow by advancing the manualization for knowledge sharing within the company.

-

FLEXSCHE

FLEXSCHE

-

By the way, I heard that UIS has also developed a scheduler called "LaPSS" specialized for environmental analysis businesses based on FLEXSCHE. What kind of product is it?

-

Hirata

Hirata

-

"LaPSS" is a system for the environmental analysis industry, such as soil analysis, not for the manufacturing industry. It is a process management system that realizes "visualization of lab management," "visualization of lab operations," and "visualization of lab issues" by collecting results from schedule planning based on unique analysis processes and test methods.

-

FLEXSCHE

FLEXSCHE

-

It seems that the scope of FLEXSCHE's activities is expanding even further.

-

Otsuka

Otsuka

-

Yes. "LaPSS" is a product deployed in non-manufacturing industries, but separately, we have recently made it possible to link our core system "UP-One" with FLEXSCHE. It was a long-standing wish to connect software with the letter "U" from UIS and FLEXSCHE, so we are delighted.

-

Asami

Asami

-

We recently received the first order for that project. We expect that the linkage between FLEXSCHE and UP-One will further help our customers.

Message to the manufacturing industry

-

FLEXSCHE

FLEXSCHE

-

Lastly, if you have a message for those in the manufacturing industry who are interested in FLEXSCHE, please share it with us.

-

Asami

Asami

-

Systematizing planning operations offers a significant cost-benefit compared to other operations, and establishing it early can bring substantial benefits. FLEXSCHE regularly expands its features through version updates, so you can expect increased effectiveness even after implementation. Therefore, we recommend early adoption.

-

Kazuki

Kazuki

-

There is no product more superior in flexibility and operability than FLEXSCHE. It is a tool that will surely assist in solving your challenges. You can start by implementing it in just one part of the process to achieve results, and eventually expand it throughout the entire company. Please feel free to consult with us first.

-

Otsuka

Otsuka

-

FLEXSCHE seems like a system for planning and scheduling, but it is also a system that can be useful for managing the entire factory and company. We hope you will expect effects beyond mere cost reduction, production efficiency improvement, and visualization.

-

Hisaka

Hisaka

-

We have a production planning system specialist SE who has handled dozens of cases, so we should be able to provide a system that is more helpful to our customers by using our experience and examples as hints.

| Return to HOME |