FLEXSCHE CarryOut

FLEXSCHE CarryOut

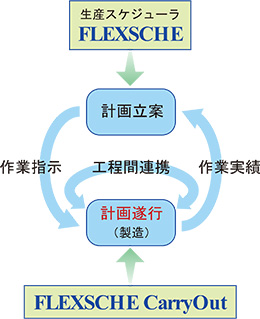

The manufacturing plan devised by the scheduler is maximized in value only when it is properly executed on the manufacturing floor. FLEXSCHE CarryOut is a system that supports the establishment of a smooth planning operation cycle.

No matter how excellent a plan is devised, if it cannot be executed properly, it is just a pie in the sky. FLEXSCHE CarryOut's role is to support the realization of orderly production activities based on the schedule while appropriately dealing with various fluctuations that may occur on the manufacturing floor, such as sudden changes, troubles, and temporal fluctuations.

*carry out = "to execute or accomplish (instructions or plans)"

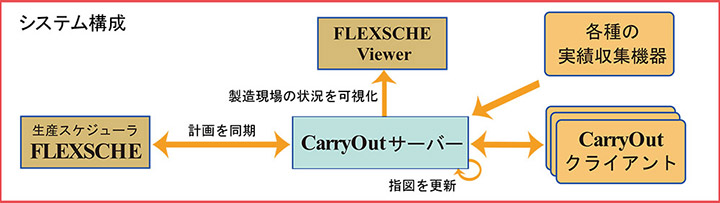

FLEXSCHE CarryOut consists of server products and client products.

CarryOut Server

The "plan" devised with FLEXSCHE becomes "results" when executed on the manufacturing floor, and various information such as start/completion times, machines/people who performed the work, and quantities of raw materials used are updated. The CarryOut server receives and reflects this information sent from CarryOut clients and other various result collection devices. Furthermore, even if the plan becomes unfeasible due to delays or troubles, the original plan can be updated to obtain the latest executable instructions at any time.

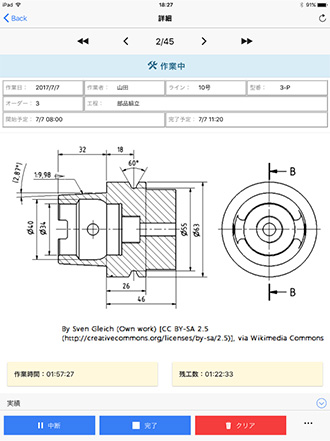

CarryOut Client

The CarryOut client is an app that runs on iOS/Android/Windows tablet devices. This app communicates with the CarryOut server to retrieve and display the latest work instruction information sent from FLEXSCHE, and send the entered work result information to FLEXSCHE via the CarryOut server.

The screen layout and display items can be freely customized for each user. You can change the item names to suit individual users and display only the information you want to show.

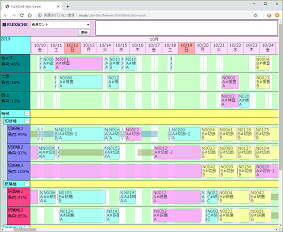

Displaying Gantt Charts

The latest work status of the manufacturing floor held by the CarryOut server can beFLEXSCHE Vieweror using the attachedFLEXSCHE Web Viewervisualized in real-time as a Gantt chart.