Plan with limited space and time constraints

Workshop Planning Option

This is a groundbreaking optional product that addresses the "interference in the placement of manufactured items" that previous production schedulers could not handle.

For producing large-scale manufactured items ranging from several meters to several tens of meters, interference in the placement within the workshop is a critical issue. The "Workshop Planning Option" enables planning through automatic scheduling and manual adjustments while considering the placement of items as constraints.

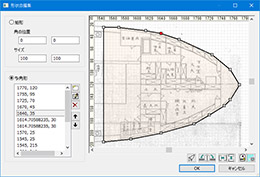

Definition of Shape

You can graphically define the shape of the workshop and the shape of the manufactured items (workpieces). When inputting shape data, you can easily add vertices with the mouse, similar to a drawing tool. During this process, you can display a reference image in the background and plot on top of it. Additionally, you can define areas where workpieces cannot be placed (such as entrances, columns, and passages). Shape data can also be imported from external databases.

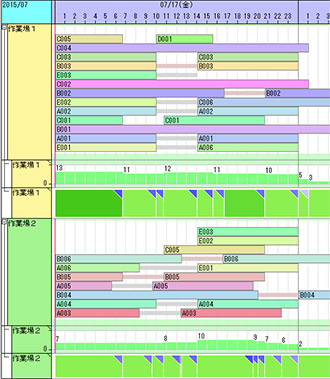

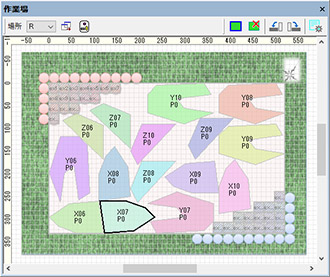

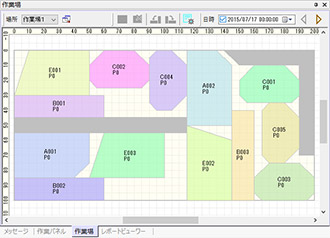

Visualization of the Workshop

The arrangement of the workshop and manufactured items at a certain point in time is displayed on the workshop panel. You can drag and move the manufactured items with the mouse to fix or rotate them. When you move the mouse cursor or click on the task segment display of the signboard row placed on the timeline chart, the state of that time period is displayed on the workshop panel. The signboard row also displays the occupancy rate and violation status for that time period.

You can also display an image in the background of the workshop panel. By overlaying it with an actual image of the workshop, you can more easily grasp the placement locations of the manufactured items.

Planning of Workshop Layout

Scheduling can be done so that the manufactured items do not overlap each other and fit within the workshop, using the shape of the manufactured items and the state of the workshop as constraints. Furthermore, you can move and fix the manufactured items with mouse operations, or if necessary, deliberately create overlapping states and schedule while maintaining them.

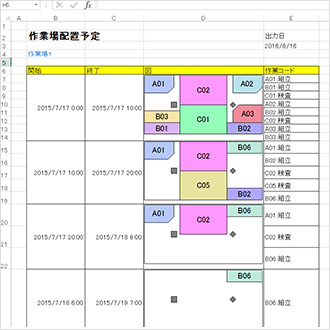

Output of Workshop Planning to External Sources

There are various methods to output the results planned with the Workshop Planning Option to external sources.FLEXSCHE EDIFUsing it, you can export data to databases or CSV files. At that time, graphic data in EMF or SVG format can also be output together, allowing it to be imported and utilized externally. By using the Excel report function of FLEXSCHE EDIF, you can export reports including layout diagrams. Alternatively, with an external method on FLEXSCHE, you can process the SVG files output by FLEXSCHE EDIF and display or export them as web pages (HTML files).