Adjust the supply-demand balance in forecast production

FLEXSCHE d-MPS

FLEXSCHE DMPS

Industries such as daily necessities manufacturers and food manufacturers, which always produce while forecasting demand, or industries such as automotive parts manufacturers and electronic parts manufacturers, which are forced to produce in advance based on preliminary information, are constantly troubled by "demand uncertainty and short-term fluctuations." Controlling product inventory levels to fill the gap between daily production volume and confirmed demand is a daunting task. Neglecting even a little the skillful operation of the accelerator and brake for each of the many product types will quickly lead to unnecessary product inventory piling up, or conversely, sudden stockouts occurring, causing the manufacturing site to be thrown into confusion by fluctuations.

Is it because the accuracy of demand forecasting is low? Was the inventory level too low? Is it because the frequency of production-sales adjustment meetings is low? The essence of the problem is not such things. The problem is the lack of a mechanism to foresee potential troubles and respond quickly and appropriately. Accurately simulating the future, comparing and monitoring the transition of the predicted demand quantity and the supply quantity by the factory, and responding promptly when necessary is the correct way to deal with "demand uncertainty and short-term fluctuations."

Moreover, the demand quantity, which has a probabilistic range and fluctuates daily, should not be directly used as the request quantity to the factory. By independently determining the request quantity while referring to the future demand quantity transition, it is possible to protect the manufacturing site from confusion and respond promptly when a red light is lit.

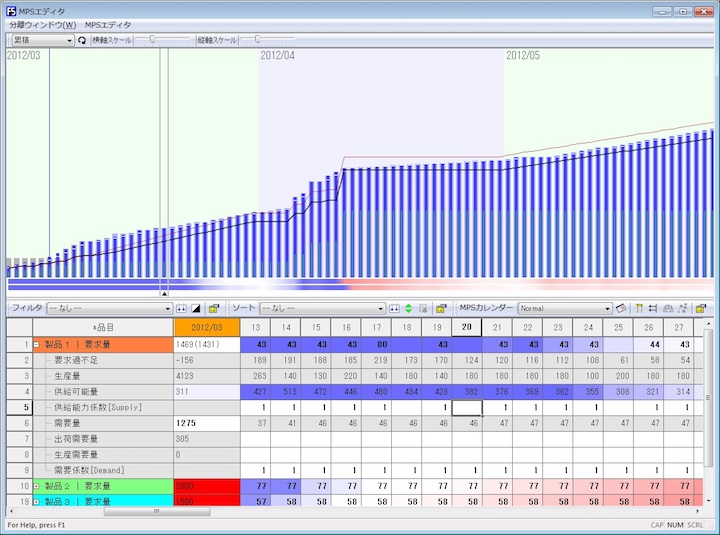

Visualizing and correctly understanding the balance of the transition of demand quantity and supply quantity by the factory from the past to the future. Appropriately determining the request quantity to the factory based on that. And seeking the supply quantity based on the factory's accurate production capacity. These cannot be realized in the conventional MPS (Master Production Schedule) and production-sales adjustment process-dependent business cycle.

Constantly monitoring the future supply-demand balance, foreseeing surpluses and shortages, and promptly and accurately adjusting the request quantity... This is a new production planning solution that directly responds to the manufacturing industry's earnest desire to deal with "demand uncertainty and short-term fluctuations," which was previously impossible to achieve.FLEXSCHE d-MPS.