Advanced Modeling and Constraints

To accurately respond to the diverse demands of the manufacturing industry, a considerably high level of expressiveness is required, and it is also necessary to efficiently model vast amounts of data. The ability to flexibly combine various functions prepared for this purpose is a major strength of FLEXSCHE. This page introduces some of the mechanisms provided to express advanced modeling and constraints.

* Even more advanced and specialized mechanismsAdvanced Optionare provided as needed.

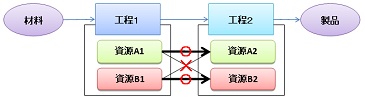

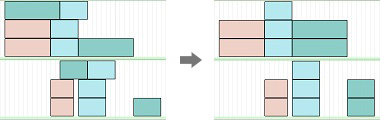

Line Constraint / Resource Connection Constraint

You can restrict the combination of resources used in the upstream and downstream processes. There is a simple "Line Constraint" that defines the belonging line for resources, and a "Resource Connection Constraint" that allows for complex settings such as restricting only specific processes or imposing constraints between sub-resources.

Parametric Process Definition

When a series of processes for manufacturing a product is similar to another product, you can share the common parts and define only the differences individually. This reduces the amount of data and makes maintenance easier. Additionally, various customizations are possible for the method of calculating quantities when generating operations from orders.

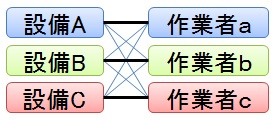

Combo Key

You can easily specify the combination of resources used simultaneously by a single operation. This is useful, for example, when a person in charge is assigned to each piece of equipment.

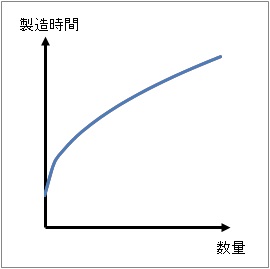

Defining Operation Timespan with Expressions

You can define operation timespan using expressions. This allows you to express cases where the manufacturing time changes complexly depending on the production quantity.

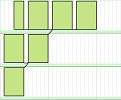

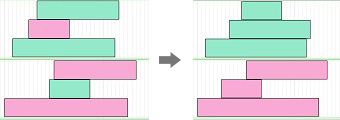

Parallel Condition Constraint / Simul-loading Constraint

The parallel condition constraint allows only operations with the same conditions to be executed in the same time range. The simul-loading constraint adds that operations start and end simultaneously.

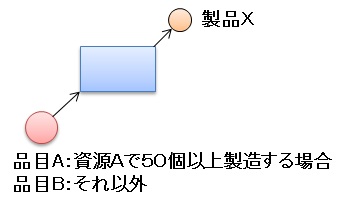

Dynamic Item Selection

You can determine the items used by an operation or the items produced as by-products according to a conditional expression when assigning the operation. For example, you can switch the raw material item used depending on the assigned resource.

Process Template and Item Recipe

If process definitions can be patterned, you can share templates from multiple process definitions and describe only the differences as a delta, making data maintenance easier (Process Template).

Additionally, you can separate the definition of individual raw materials from the process master and provide them from each order (Item Recipe).

The expressions that can be described in various parts of FLEXSCHE become a powerful tool for realizing flexible operation/modeling/scheduling.

- Various evaluation values and conditions in scheduling rules

- Various constraint conditions and capacity values in master data

- Specification of display color and display string on the chart

- Chart Row Configuration Rules

- Specification of file paths

- Display content and filter/sort conditions in FLEXSCHE Editor

- Data mapping in FLEXSCHE EDIF, etc.

The user interface for entering expressions is also well-equipped.