The Concept of FLEXSCHE

Now is the time for a truly usable

Production Scheduling System!

The manufacturing site is forced to operate much more meticulously than ever before, with the transition to multi-product, small-lot production, the demand for quick delivery responses, and frequently changing production plans. Regardless of the industry, the process of continuously making things in factories is truly a constant battle against time.

In an environment where the manufacturing industry is undergoing significant changes, continuing traditional production activities based on static information and rough plans, which are "sliced" at the "present," is fundamentally difficult. The production scheduler FLEXSCHE directly solves the problems faced by such manufacturing sites.

A system that is not used

has no value

The purpose of our activities is not merely to "sell" "FLEXSCHE." This is because we believe that a system that is not effectively used after its introduction has no value. The business objective of FLEXSCHE is to confidently introduce the production scheduler "FLEXSCHE" to more factories and have them continue to use it for a long time, steadily achieving results. To that end, we support the improvement of users' utilization skills. We are diligently nurturing "FLEXSCHE."

We want to share dreams with the manufacturing industry!

Our dream, which is both near and far... We dream of the day when we can say, "Finally completed!" with all the functions required by the manufacturing site implemented in the "Production Scheduler FLEXSCHE." However, in reality, that will be a distant future. This is because the demands from the manufacturing industry are so diverse and profound that even if we solve one with all our might, the next challenge is immediately presented. However, responding to these endless challenges is our responsibility and motivation for our activities. We at FLEXSCHE wish to stay close to our users, constantly solving their challenges, and continue to aim for the horizon of manufacturing that can be seen in the distance.

What is important is "flexibility"

"Flexibility" is the source that enables diverse and advanced modeling capabilities and thoroughly realizes what you truly want to do. "Flexibility" is indispensable for overcoming unexpected obstacles that become apparent during implementation and for the continuous growth of the system after implementation.

With "flexibility," unnecessarycustomizationcan also be avoided.

For continued use,

"Ease of Use"

Another important aspect is that planners continue to use it steadily every day. A system that is difficult to use will gradually fall out of use. Therefore, the "ease of use" that cannot be read from the product catalog is also important.

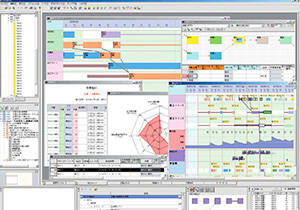

The production scheduler developed and sold by FLEXSCHE CorporationFLEXSCHEis

- designed to adapt to the needs of various manufacturing industries withflexibility

- and to ensure continued use withease of use

in a high-dimensional balance. The fast scheduling and rendering processes, easy-to-view screens, and smooth operability are also attractions of FLEXSCHE.