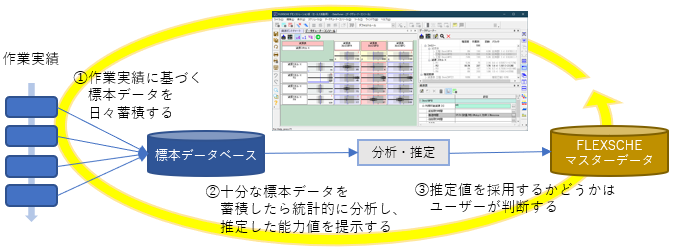

Estimate process capacity values based on accumulated operation result information

FLEXSCHE DataTuner

FLEXSCHE DataTuner

"Creating highly accurate plans that align with reality" is one of the major challenges in production scheduling. For this, it is a necessary condition to "appropriately assign" the capacity of each process.

However, it is not always possible to grasp the capacity of all processes from the start, which is a troublesome issue in many implementation projects. Moreover, since most processes have temporal "fluctuations," reasonable values cannot be determined without repeated measurements.

FLEXSCHE DataTuner contributes to the formulation of highly accurate and reasonable plans by accumulating sample data of operation times based on operation results daily, calculating estimates from statistical processing results, and presenting them.

Update capacity values based on estimates

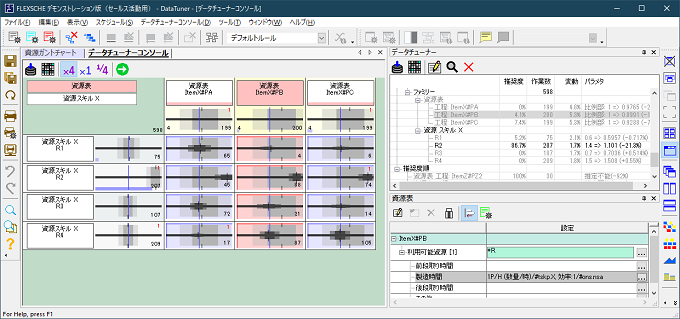

After the operation of FLEXSCHE DataTuner begins, a sufficient number of sample data will accumulate over time, allowing for analysis. The relationship between the current capacity values, newly estimated capacity values, and the distribution of sample values is visualized, and the "recommendation level" of the new capacity values is also presented, enabling users to quickly and intuitively update capacity values.

Data Tuner Console (left) and Data Tuner Panel (right)

(If capacity is parameterized by skills or numerical specifications, it is analyzed in multiple dimensions)

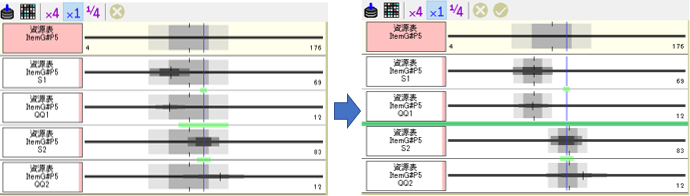

It is also common to assign a common capacity value to multiple machines considered to have the same performance, but upon actual use, significant capacity differences are found. When FLEXSCHE DataTuner detects this difference, it visualizes and presents a division proposal, allowing for easy division of capacity definitions.

Before (left) and after (right) splitting capacity value settings

Confirm the coexistence of resources with different capacities, and split with just a double-click operation

By utilizing these mechanisms, you can initially assign rough capacity values and gradually subdivide and detail them, making it easier to build a production scheduling system.

In conjunction with FLEXSCHE CarryOut

Statistically reasonable plans form the foundation for appropriate plan execution, but they are not sufficient on their own.

As mentioned above, "fluctuations" hinder manufacturing according to plan. It is important to accept and adapt to "fluctuations" while executing plans, and FLEXSCHE CarryOut provides the mechanism for this. Proper operation of FLEXSCHE CarryOut naturally yields accurate result information, creating a complementary relationship that kills two birds with one stone.

Sample data can be accumulated regardless of whether you have a license for FLEXSCHE DataTuner.